What do you do about storing 250 diverse types of clamps used by 24 Furniture Design Program students? The Sam Beauford Woodshop was growing driving the need for more woodworking clamps. Our goal was to store all the needed clamps in as little space as possible, keep the storage system flexible and organize it so students would be able to quickly find their needed clamp.

Read MoreEver since I was a kid I had an interest in woodworking. But my family never really had woodworking tools so I couldn't possibly learn at home. When I got to high school I jumped at the opportunity to take Woodshop where I did learn about some of the basics of woodworking, but I was more concerned with the social constructs of school than I was of truly committing myself to the craft of woodworking.

Read MoreThe thought of retirement was very scary to me because I was defined mostly by my job. Sure, I was a husband and a father, but most of my time was spent being an engineer and/or project manager.

Read MoreOur current class of Wood Design: Furniture Making students began their journey with us on Aug 18th, 2023. Some were very experienced woodworkers, others had no experience at all. They came from very diverse backgrounds, and from locations all over the United States… and the UK! Out of 20 students, 16 of them left their home and moved to Adrian to attend this college woodworking program.

Read MoreThe essence of a handcrafted Windsor chair lies not just in its graceful form but also in the intimate relationship between the craftsman and the raw materials. This age-old art, steeped in tradition, carries a deep understanding of the wood grain, the rhythm of hand tools, and the mastery of listening and responding to the wood.

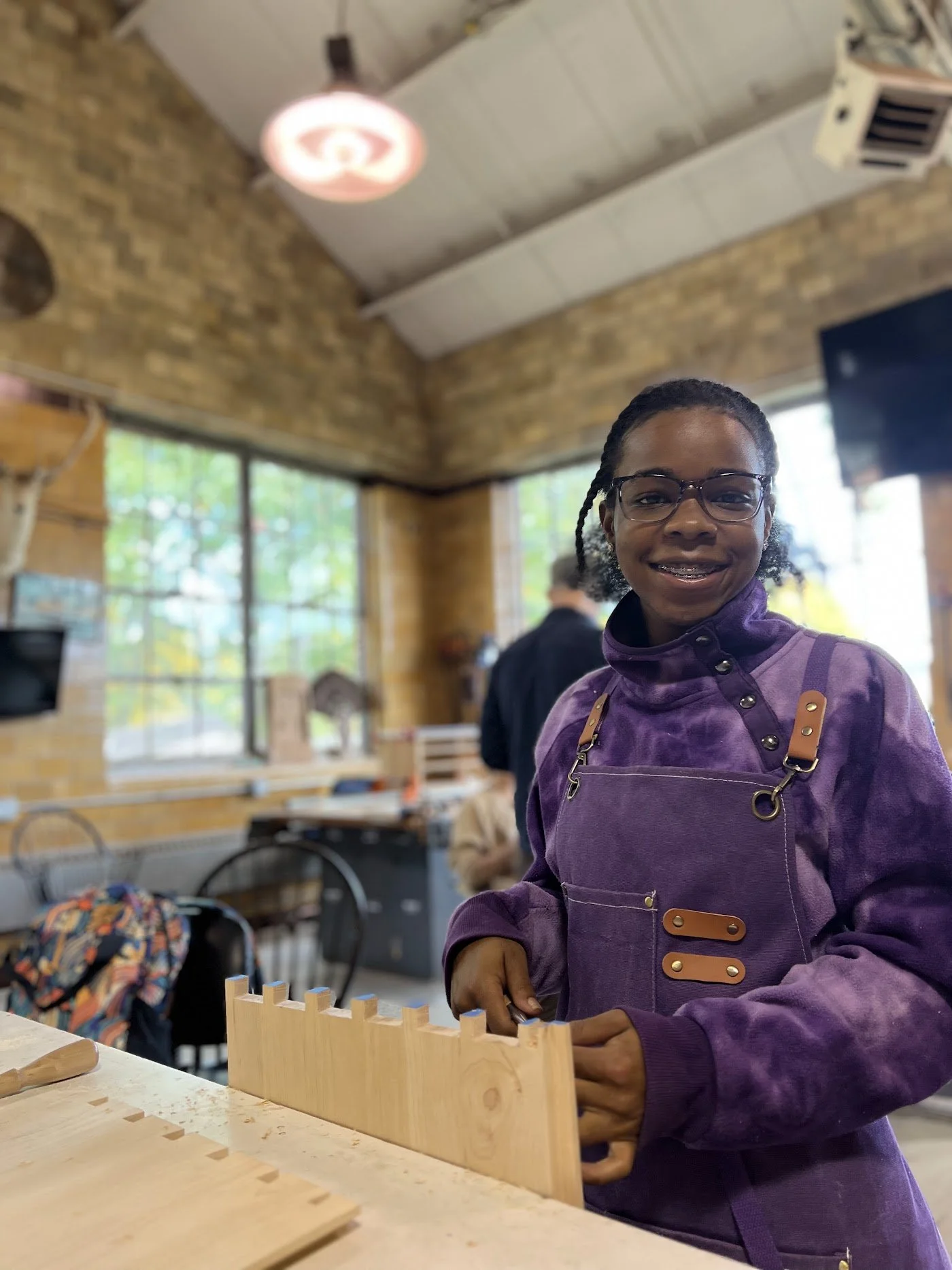

Read MoreCatapults with kids! The Sam Beauford Woodworking Institute partnered with Lenawee Great Start to offer a catapult building workshop during the PlaneWave Open House on October 7th. During the workshop kids were assisted by staff, volunteers and family members to construct their own catapult and then shoot marshmallows into the woods.

Read MoreMany of you may have seen the timber frame pavilion structure standing in front of our school for the past 4 months. This timber frame structure was built by Sam Beauford Woodworking Institute (SBWI) students in May of this year during a 5-day timber frame workshop with jack Witherington. They built and raised the timber frame structure in front of our classroom to be on display during the Great Lakes Woodworking Festival.

Read MoreWhat a historic week!!! We are beyond elated to announce the completion of the first ever helical staircase course offered in North America. Students of the SBWI completed this course with grand success and demonstrated their skill and competency by constructing their own scaled-down model of a spiral staircase.

Read MoreIt’s pretty common for our Windsor Chairmaking students to think of questions after attending one of our 5-7 day classes. It is inevitable as you bring your chair home and start to think about the finish and showing it off to your family and friends, that you might notice an imperfection here or there, or wonder … how much Milk Paint should I purchase??

Read MoreSteve McCarroll served in the US Army for 24 years. In January, 2020, he registered to become a Woodworking Warrior. He took the safety course (which is required for all veterans to use the shop) and then thought “What do I do now?”

Read MoreI've got all the bling on the boat and the last of the varnish on the decks and gunwales. I'm going to shoot another coat or two on the hull. I've got some varnish drips and a few spots of glue from putting the gunwales together that I want too sand out before I call the boat done.

Read MoreSneak preview! I've gotten most of the bling fastened to the boat and some of the finish. I screwed the stem bands to the stems and hung the carrying handles today and got another coat of varnish on the wood parts of the boat. The next time I get a sunny day I'll try to get the boat outside and get some better close up shots of details on the boat.

Read MoreEvery Windsor Chair Making class is an immersive, unforgettable experience. It is a week of hard, grueling work followed by pride and accomplishment at making an object so incredible it will last well beyond your lifetime. Last month, a father and son, Dean and Ryan Ramsey joined us to build Windsor Continuous Arm Chairs.

Read MoreTwo more things to sand. Canoes generally have a center thwart, something going from one side of the canoe to the other which gives the hull more rigidity. Small solo canoes like this one have the paddler near the center of the boat where a center thwart would be in the way.

Read MoreThis is what I had in mind when I said to remember all the goopy resin on the decks and gunwales. I've burned through a pile of sandpaper in the last 3 or 4 days and I've got most of the sanding done. I used the random orbital sander with 100 grit pads to knock most of the resin off and then worked up through 120, 150 and 180 grits by hand. I had nice weather the last two days so I moved outside to do the sanding. That keeps the sawdust out of the shop but more than that, natural sunlight shows sanding imperfections better than any lights I have inside the shop.

Read MoreStem bands. The stems are like the bumpers on a canoe. I like to finish a canoe with brass bands on the leading edges of the stems. The functionality is questionable but they sure have a nautical look. A mill file to shape the ends, sand paper and steel wool to polish them and they're ready to go on the boat. They'll just be screwed on, not glued so they can be taken off the boat to re-polish them when the brass loses its shine.

Read MoreLike I hoped, today I was able to finish fastening all of the pieces of cherry that make up the gunwales. Everything is glued and screwed and I'll leave the boat alone and go enjoy the weather outside.

Read MoreI've gotten the decks mostly machined and I'm putting a finish on the underneath sides as it will be harder to do once they are in the boat.

Read MoreThis is not a drill, I repeat this is not a drill (that's for you Chuck). There won't be any more fitting and adjusting on the pieces that make up the gunwales. The inner pieces are glued and screwed where they are going to stay.

Read MoreThe weather was nice yesterday and I had a marathon sanding session with the random orbital sander outside. The wood hull is sealed in epoxy resin and all of the sanding that I'm doing now is on the resin.

Read More